Full Turnkey Assembly

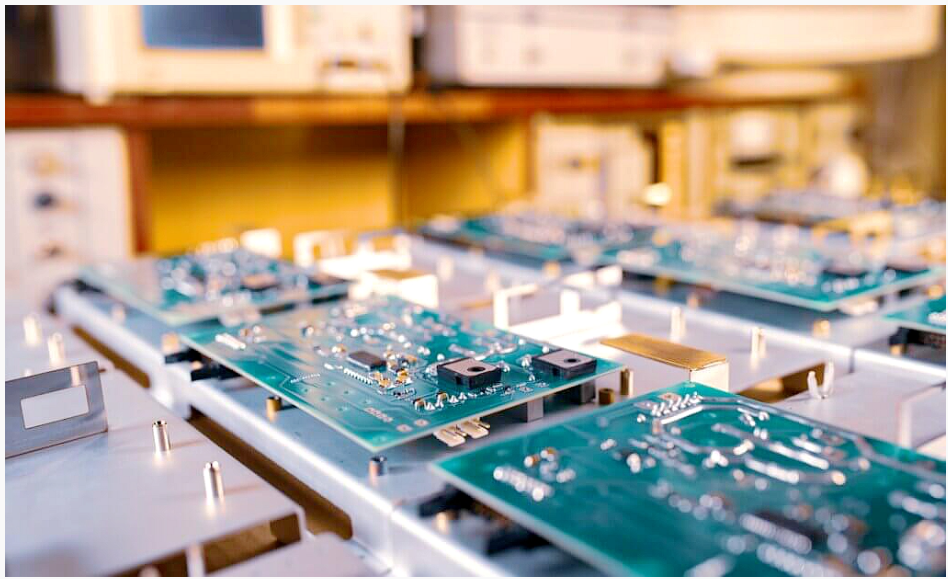

At Rush PCB Inc., we bring your electronic visions to life. Nestled in the heart of Silicon Valley, we’ve been at the forefront of PCB (printed circuit board) production for over twenty years. We offer comprehensive turnkey manufacturing solutions, including PCB design, fabrication, assembly, and testing.

With huge investments in the latest circuit board manufacturing equipment. Rush PCB now offers turnkey PCB assembly services for the benefit of all types of hardware makers, especially startups. We can give you high quality circuit boards even at low volumes at affordable prices. Not only do we help design your boards, but also order parts according to your BOM supplying you a fully assembled PCB. In short, we take care of all your PCB requirements from design to assembly. You can get your PCB fully assembled and tested, ready to mount inside your product. Our turnkey electronic PCB assembly facilities can bring you several benefits.

Full Turnkey PCB Assembly and Manufacturing

The word ‘turnkey’ applies to a product or service ready for immediate use by the customer. As applied to PCB assembly, it means the supplier will handle the complete PCB project. It includes procurement of electronic parts, other components, manufacturing the PCB, and the complete assembly and testing.

Most turnkey PCB assemblers use Internet cloud-based software. They liaise with PCB manufacturers to develop printed circuit boards, and with component suppliers to obtain components. Rush PCB, on the other hand, has its own in-house PCB manufacturing facilities and is able to help customers right from the design stage. Not only is this more efficient and cost-effective for small businesses. It is also very effective, especially when the time to market is critical for the customer. Essentially, with our full turnkey electronic PCB assembly solutions, you can focus more on the development of your product, leaving us to handle the rest of your operations.

Two Types of Turnkey PCB Assembly

PCB turnkey services are not limited to just PCB assembly and component procurement. Vendors provide different turnkey PCB assembly service packages. Some of the common types are –

Full Turnkey PCB Assembly– Most of the vendors name it as just Turnkey PCB Assembly. In such services, the vendor handles all the aspects of the PCB assembly. The vendor is responsible for the procurement of all the components and PCBs involved. This service sometimes also includes functional testing. Some vendors may also offer cheaper components of the same functionality in such services. It is recommended to avail full PCB turnkey assembly as PCB vendors are experts in procurement and have sources that small businesses and sole engineers cannot access.

Consigned Parts PCB Assembly Turnkey – Many vendors also use the term “partial turnkey PCB assembly service”. In this type of turnkey PCB assembly some parts are provided by the customer and the rest of the parts are to be procured by the Vendor. The parts consigned may include PCB, ICs or any other component to be assembled on the PCB. Such service may be used if you have spare PCBs or are using special or confidential ICs that cannot be procured by other channels.

Advantages of Full Turnkey Electronic PCB Assembly

Whether you are a startup, a small business, or an established OEM. You can utilize our full turnkey electronic PCB assembly services to invest smaller amounts in printed circuit boards without having to carry a huge inventory. Our turnkey services provide you an efficient and cost-effective solution to assemble and test circuit boards. Furthermore, we give you fully assembled and tested PCBs within the shortest possible lead times.

Effective Management

Collaborating with Rush PCB. As your full turnkey PCB supplier, you have only one vendor to manage. This saves you the frustrations of having to manage several independent vendors for components, parts, and PCB. When you are working with us as your turnkey partner. You will have only a single point of contact. This also means you have a single bill, and we will seamlessly handle any changes you want in the project. We understand that developing prototypes is a time-consuming and expensive process. Along with it, managing multiple vendors is oftentimes overwhelming.

High Quality Products

Our customers benefit from our professional services. We offer you exceptional quality boards, expert soldering of surface mount components, and fully tested assemblies. As a professional turnkey PCB assembly and manufacturing facility, we only use high quality laminates, solder resist/coverlays, and silk-screening methods.

For several reasons, including intellectual property protection, most customers prefer to have surface mount devices (SMDs) on their PCB rather than use through-hole components. As SMDs require professional assembly using precise automated placement and a reflow oven for effectively soldering them, manual assembly and hand-soldering leaves much to be desired in terms of quality.

To obtain perfect solder joints on very small SMD parts and fine pitch components. We use the latest automated machines and techniques. Therefore, we can offer you the most reliable turnkey electronic PCB assembly solutions in the market.

Design for Manufacturing

One of the key advantages of the professional turnkey solutions we offer is free design for manufacturing (DFM) facility. When you collaborate with us for a prototype. We review your design before production, and assess the design for its fitness for manufacturing. Our team will bring to your notice any part of your design that may cause an issue with manufacturing, and offer our suggestions to overcome the issue.

When you supply us with a netlist file, we can detect errors in the routing of your prototype board that may have crept in when creating your board layout. Identifying errors early on at the prototype design stage is far cheaper than making changes in the final product. We have experienced PCB designers for conducting DFM checks in your design. It will save you time and money by preventing mistakes slip by to your final product.